Funding from the European Regional Development Fund (EFRE)

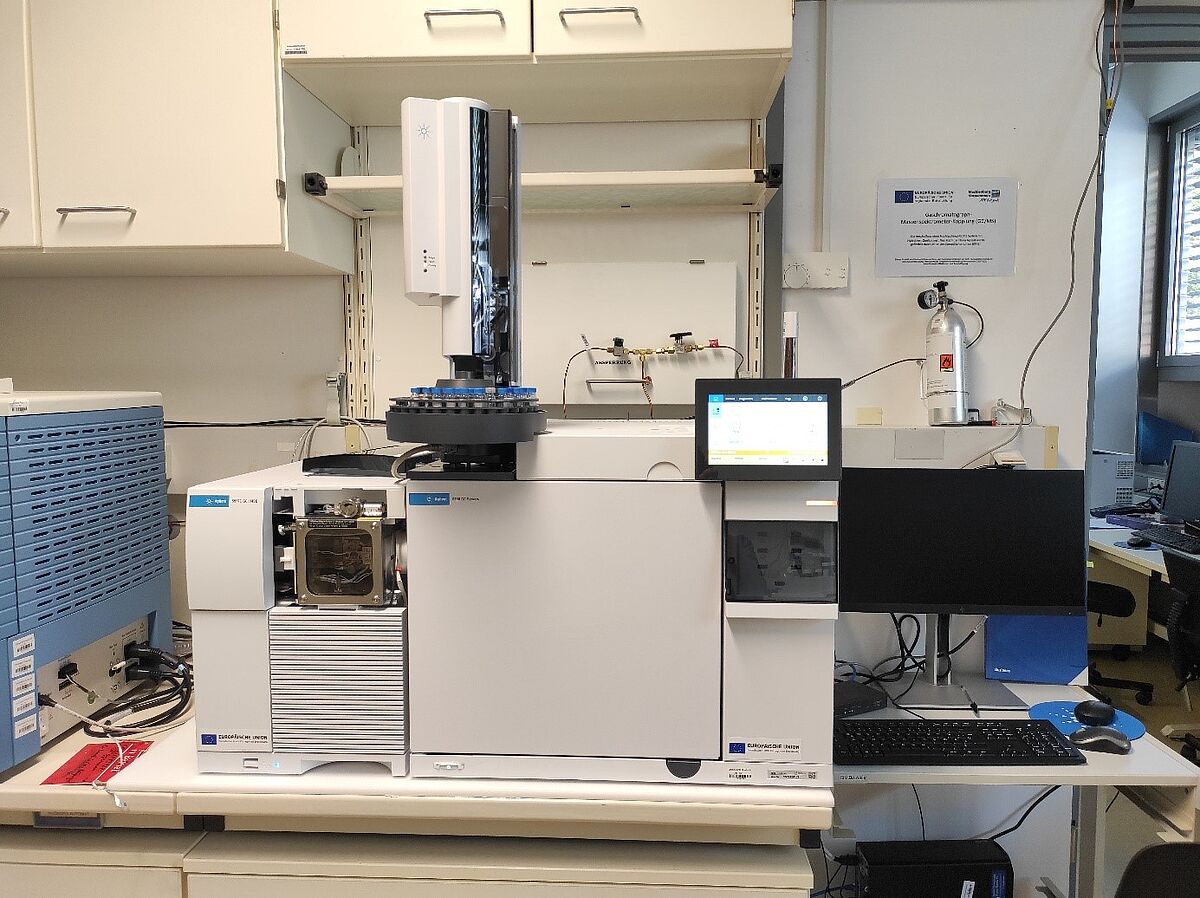

Thanks to a grant from the state of Mecklenburg-Vorpommern and the European Union, respectively, from the European Regional Development Fund (EFRE) for the measure "Promotion of research competencies at universities and non-university research institutions - scientific equipment", the acquisition of a new high-performance GCMS system with HydroInert source could be realized in 2023.

The equipment procured is a high performance GCMS system with HydroInert source from Agilent. The HydroInert source offers the highest efficiency for hydrogen carrier applications and is currently the company's unique selling point on the market. It offers the highest spectral fastness for substances that are sensitive to hydrogenation and results in excellent peak shapes for high-boiling substances, especially for polycyclic aromatic hydrocarbons (PAHs). In addition, the instrument has very high sensitivity down to the femtogram range. The detectable mass range here is between 1.6 and 1050 u. A high scan rate of 20,000 u/sec ensures reliable spectra through more measuring points and also enables synchronous SIM/scan operation.

Furthermore, the device offers excellent reproducibility, which is among the best of the devices available on the market. This is achieved by high bakeout temperatures in the inert source and the transfer line and also in the quadropoles. This bakeout removes impurities and also increases the long-term stability of the ion source. Gain Normalization Autotune also allows the Electron Multiplier (detector) voltage to be normalized, ensuring consistently reproducible quantitation of all analytes over time. In addition, the Retention Time Locking function (RTL) allows retention times to be "frozen", ensuring the highest standard of qualitative determination of substances. The effects of changing chromatographic conditions, such as shortening the column, then no longer have a negative impact on chromatography.

The additional possibility of chemical ionization (CI) gives us more scope for application-oriented investigations. Usually, molecular ions are first detected in the MS and determined in the analysis. If this works well, data analysis for structure elucidation, such as impurities in production streams or even natural product samples, is straightforward. In some cases, however, electron impact ionization does not produce molecular ions or cannot detect them, or is even difficult to confirm due to its relatively weak intensity. CI, however, is a much gentler ionization method than EI. Here, fragmentation is less likely to occur, making information about analyte molecular weight much easier to obtain. With this ionization method, molecular ions can be easily measured, for example, even for components with large molecular weights, such as TMS derivatives of sucrose.

Furthermore, the system has two filaments for ion generation. If one filament fails, work can continue immediately with the second filament. The routine can be continued smoothly or without interruption and a time-consuming filament exchange can then be performed in the next standby mode of the instrument. This feature greatly minimizes unnecessary downtime or even sample loss can be avoided.

Another significant advantage is the high flexibility in the choice of carrier gas that is used. The system offered by Agilent is suitable for hydrogen as a carrier gas and has been extensively tested for all applications with hydrogen. This means that we can switch between the two carrier gases without further major conversion measures, irrespective of bottlenecks or price increases for helium. This is associated with higher chromatographic performance due to shorter run times and higher separation performance of the analytes. This allows us to work in a much more future-oriented manner, also with regard to the ongoing operating costs of such a system.

The new GCMS system is thus an ideal tool for dealing with the demanding analytical problems in the "Technical Chemistry" working group at the Institute of Chemistry.