- Großeheilmann, J.; Vanderveen, J. R.; Jessop, P. G.; Kragl, U., Switchable‐Hydrophilicity Solvents for Product Isolation and Catalyst Recycling in Organocatalysis. ChemSusChem 2016, 9 (7), 696-702.

- Großeheilmann, J.; Büttner, H.; Kohrt, C.; Kragl, U.; Werner, T., Recycling of Phosphorus-based Organocatalysts by Organic Solvent Nanofiltration. ACS Sustainable Chem. Eng. 2015, 3 (11), 2817-2822.

- Illner, S.; Hofmann, C.; Löb, P.; Kragl, U., A Falling-Film Microreactor for Enzymatic Oxidation of Glucose. ChemCatChem 2014, 6, 1748-1754.

- Liese, A.; Kragl, U., Einfluss der Reaktorkonfiguration auf die Enantioselektivität einer kinetischen Racematspaltung, Chem. Ing. Tech. 2013, 85, 826-832.

- Liese, A.; Zelinski, T.; Kula, M.-R.; Kierkels, H.; Karutz, M.; Kragl, U.; Wandrey, C., A novel reactor concept for the enzymatic reduction of poorly soluble ketones. J. Mol. Catal. B: Enzymatic 1998, 4 (1), 91-99.

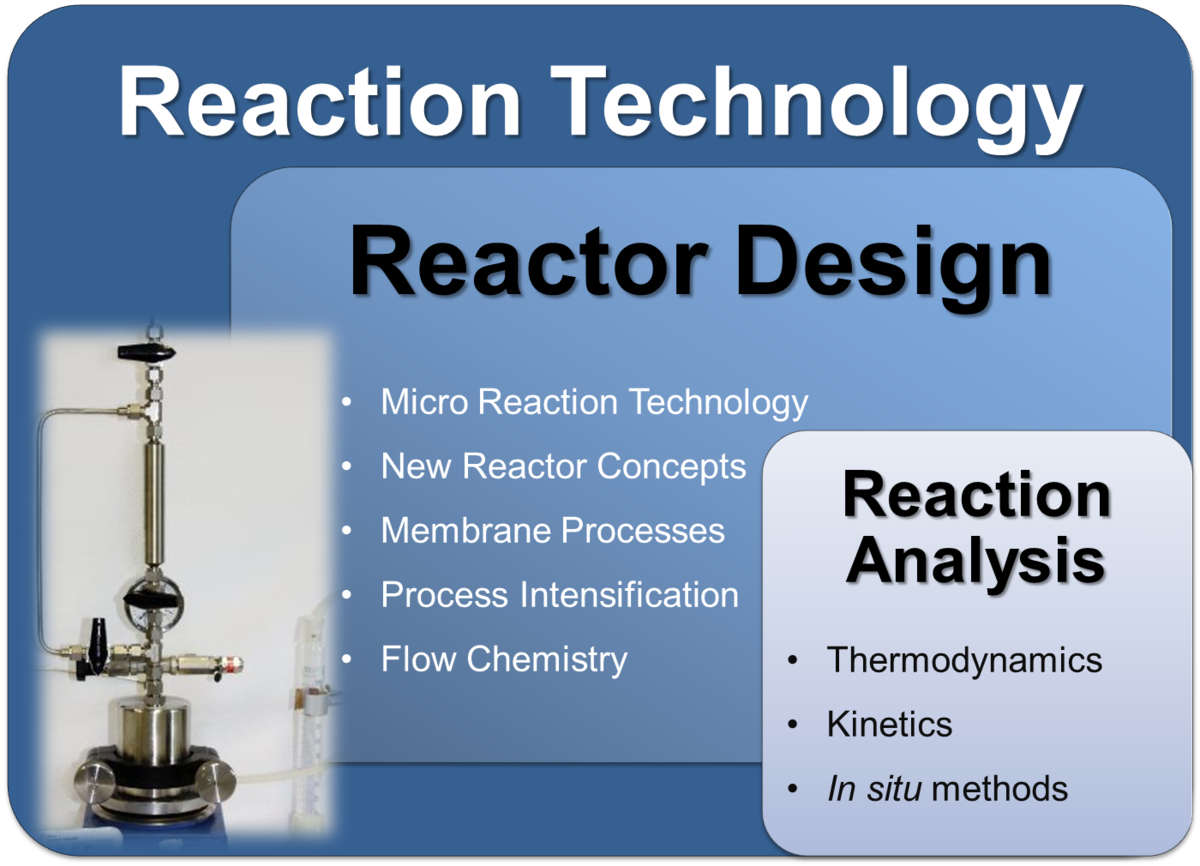

In the field of reaction engineering, we are concerned with the development and optimization of chemical and enzymatic processes. The interaction of reaction kinetics and thermodynamics with transport processes in the reactor are investigated and analyzed using modernin situ measurement methods. The focus here is the development of novel and improved processes, which can be realized for example by means of new reactor concepts with integrated product separation or by using micro reaction technology. Particularly in the case of multiphase reaction systems, the use of micro reactors results in considerable advantages and new synthesis possibilities. In addition to continuous reaction and simple scalability, intensive heat- and mass transport as well as effective multiphase contact are the main reasons for the use of microstructured reactors. In recent years, the falling-film micro reactor (FFMR) was used e.g. for an improved O2-entry in an enzymatic oxidation of glucose as well as for a faster CO2-output in CO2-triggered switchable solvent systems in order to improve the overall process and to make it more efficient.

A reliable separation process is the membrane technology, especially organic solvent nanofiltration (OSN) has been used in our working group for many years, e.g. for the recovery and reuse of catalysts. This process offers the advantage that the sensitive catalysts can be separated from the organic solvent under mild reaction conditions. Furthermore, this process can be integrated in existing production processes, so that a continuous reaction control is possible.

Questions of process intensification towards the studied reactions, such as biocatalysis, electrocatalysis and chemocatalysis form an important part of our research.

In the future, processes that are used so far have to be made more efficient by means of a smaller number of process steps, by intensive heat- and mass transport, by the use of micro reactors and by a continuous reaction control. These questions are currently under investigation with the modular micro reaction system of Ehrfeld, Mikrotechnik BTS.